SCAC test engineer Igor Sobolev tells how the SSJ100 aircraft were tested

SSJ100 test airplanes

At the stage of test planning there was a decision taken that there would be 6 aircraft involved in testing: one for static, one for fatigue tests and 4 for flight tests.

The airframe of the first aircraft built was transferred to TsAGI(Central Aerohydrodynamic Institute in Zhukovsky) for static tests. That is a separate and important program carried out in order to check the design integrity and its elements, the aerodynamics and other essential issues. While the second aircraft that was built became the flight test machine.

The first and the third test aircraft were meant for the main test programs checking the integrity, the aerodynamics, the engines and the control systems.

As far as the type and the quantity of the test equipment installed and also the tasks performed, they were interchangeable. The two aircraft had to fly far beyond and above all the restrictions typical for aircrafts at commercial service by any air career.

During the test flights the SSJ100 reactions and behavior at minimum and maximum flight speed were checked, as well as at limit overload, during real-time icing process, at engine failure imitation and other system fault situations.

There are minimum interior and nor passenger seats in the aircraft with 95001 and 95003.production numbers(“singlet” and “triplet” respectively – as the test engineers call them tenderly).

There are only four work-stations for onboard engineers and special rails along the aisle. Why do we need these rails? According to Russian aviation rules for experimental aviation test aircraft should be equipped with the in-flight evacuation system. That is why near the front baggage area there is a special escape trunk ending with a hatch on the lower side of the fuselage.

In case of emergency the hatch is opened towards the approach flow protecting people from its pressure and let the test-engineers and pilots evacuate safely. The rails are used by the crew so that they could get to the trunk from their work-stations. Happily, there was no such situation during the tests that would acquire the usage of that escape.

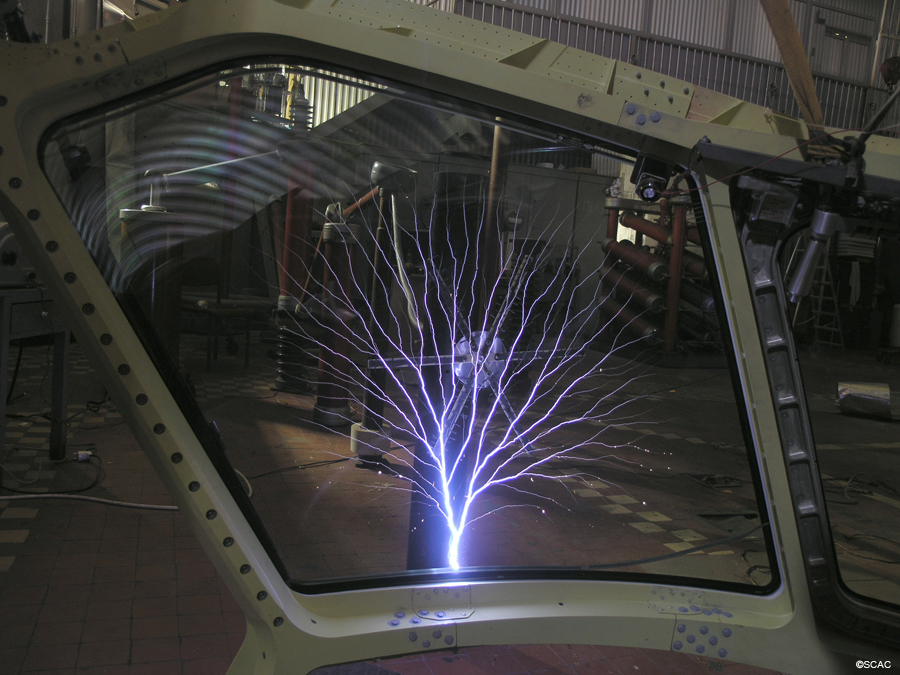

After the test flight program part was finished for the 95001, we carried out some kinds of special on-ground tests among which there was the lightning protection system testing. Modern aircraft are equipped with a lot of aviation electronics and many on-board computers and the lightning tests are divided into several stages. First stage is the simulation analysis. The second stage – the flows of currents at the lightning strike are checked at mock-ups and only after that, at the next stage, the tests can be fulfilled at the “alive” full-size aircraft.

During these tests the aircraft was stapled on big hard-rubber platforms inside the hangar so it was safely isolated from the floor and special cables were connected. The lightning might strike to the nose and go though the cover and exit through the fin or wing, or it might strike the wing or the fin and exit through the nose. During the on-ground tests we needed to check all the possible ways the lightning might go by letting the heavy currents go through the whole framework. It is necessary to be sure that the lightning strike won’t lead to system failure. The tests were a success. On the nexttwo test aircraft – ( “quadruplet” and “quintuplet”) apart from the on-board test engineers work stations the first interiors required by the Customers were installed too. The 95004 had the economy class installed and two lavatories, and the 95005 had the business-class. The two aircraft were interchangeableand used for furnishing, passenger equipment and avionics testing.

Climate tests

95004 and 95005 already had the interior installed, that is why they were used for climate tests.

The climate tests are necessary for proving the opportunity of the aircraft to work at maximum minus and plus temperatures, at high-level aerodromes and at autolanding at cross-winds.

For these tests we flew in freezing Yakutiya and north latitudes of Tiksy at the Russian Far North. High temperatures we tested in the United Arab Emirates and Kuwait, in Island there were automatic landings at maximum cross-winds and the icing was caught and tested in Archangelsk.

And the weather is often unpredictable. And sometimes we had to wait for a long time until the necessary conditions occur. When we came to Yakutiya for tests I thought that the weather there was always, so to say, applicable. But it turned out that things were far more complicated. We couldn’t catch the low temperature we needed at once there. It was winter 2012, and the locals said at once that we came in vain, because if there is -50C in December, then it is going to be even colder further on. And that year it was only -40C. And they said that we could sit and wait but there would be no cold at all that time. And I have a mug, it is a gift back from past Komsomolsk times, and I take it to all the test trips. So – it is shamanic, magical. It makes the weather we need, that was what I told them. They laughed and then came the frost! The temperature went lower and lower every day – 49, 50, 53! As we performed all the tests at the required temperature conditions, it turned “warm” again – -45°C “only”. Several days passed and the temperature went down again. After that out Yakutian colleagues said: “Guys, take you shamanic mug and go away! It is too cold!”

In Archangelsk, when we needed to catch the ice on the plane, that mug helped us too. After years and years of monitoring the meteorologists are able say where is the high probability of the required conditions of complicated icing that the test engineers need for their work.

In Russia that would be Kamchatka coast and the region between Murmansk and Archangelsk, near the White sea. And “to catch the ice”, you need to go there in April or in November. Archangelsk is closer to the base, than Kamchatka – and that is why most of Russian and Soviet aircraft performed icing tests right here. We arrived to the tests in Archangelsk in April 2009. Interestingly, there occurs a drastic change as far as the attitude of the aviators to the clear skies is concerned during the icing tests. If normally good visibility makes people happy, here during the tests they become displeased with another day lost. And low heavy clouds and the temperature a bit below zero, and snow mixed with rain would be ideal. The aim of the testing was to catch conditions as close to the worse icing, as possible. And during the five flight days five straight times the crew “caught” the applicable conditions.

Tests:in the air and on the ground

Temperature tests are performed both on ground and in the air. In Yakutsk the temperature at the flight level can decrease lower than -70°C. And we needed to show that the APU (auxiliary power unit) performs normally and starts the engines not only at the complete frozen apron but in the air as well. Notably, there should have been “delaying”: you turn the engine off and the launch is only 15 minutes later, so that the engine went completely cool, and only after that there is start, and then repeat and repeat not less than 10 times at different altitudes and speeds of flight. And as far as the heat is concerned, it is vice versa. In tropical longitudes the temperature of the air is “only” 42°C above zeroThe fuel consumption increases at once, the thrust goes low and the conditioning system is experiencing difficulties. And the experts there ask to show the launch of the “hot” engine: you turn it off and in half a minute, when it remains, so to say, white-hot, you need to start it once and once again a lot of times.

Aerodynamics and “runs” on water

Our SSJ100 is a low-winged aircraft, so the engines are located closer to the earth. And during all the tests there were absolutely no problems with the engines, even at worst conditions there were neither damage, nor unscheduled repairs or replacements. A lot depends not on whether the engines are high or low, but on the way they are installed, because they themselves do not “inhale” anything, they get only stuff that bumps from the nose gear – it all is very alike to what happens with the car. That situation is very well shown by special certification tests – the tests on the runway covered with water. The aircraft runs at different speeds through a specially made pool filled with water. The higher the speed gets, the higher the water splashes are. Finally at speed of 200km/h the water goes above the wing and reaches the level of the tail fin. But thanks to the correct aerodynamic configuration and the spacing between the gear legs and the intakes of the engines that was calculated by the SCAC engineers, nothing gets inside the engines from the runways.

Same kinds of tests are performed at the snow-covered runway with different types of snow – dry, wet and even slush. We could not catch the necessary slush texture, because the runways are always kept clean. And in the beginning of April 2012, suddenly there was snow, it was harsh, and we asked not to clean the runway in Zhukovsky. They could not give us the whole runway, but they gave us a half covered with melting snow. That day we could finalize all the tests: the take offs, the taxiing, the landings – with reverse, without reverse, with systems fault imitations and without them.

Aircraft testing after the start of serial production

According to the rules, if there is a new aircraft type prepared for the serial production and there is also a new engine installed on it – and that was what we had – it is necessary to carry out the additional test stage, the so called control certification tests. That is why together with our six test aircraft there was also the first serial involved – an absolutely standard one and made for commercial flights, with no test equipment on it at all. It was required to fly not less than 150 hours with no faults performing take offs and landings at the same airports where it is supposed to be operated in future. We asked the Customers for their destination network planned for SSJ100 and chose five regional Russian airports and started the flights with service passengers on the board. During these flights we continued to improve the aircraft, because test machine is one thing and the serial aircraft is different. From November 2010 till March 2011 the SSJ100 with production number 95007 flew with the representatives of the certification authorities on the board, and they were quite content.

Emergency evacuation demonstration

Same aircraft was used for an on-ground emergency evacuation demonstration.

These tests are restricted with a great number of rules with no disobedience allowed. There should be a completely standard aircraft standing in the hangar in the absolute darkness. It is allowed to use only the emergency exits on the one side of the airplane (left or right). The “passengers’ who take part in the test should not be familiar with the construction or operation of the given aircraft type. They do not know beforehand to which part – the left one or the right – they should be moving while evacuating. The percentage of male-female and the number of people over 50 is prescribed by the rules too. There is a number of dolls of characteristic size and weight to perform the role of babies, and some passengers need to evacuate with them in their arms. The illuminators should be covered with curtains and there should be bags and suitcases thrown all over the aisle as if it is baggage fallen out of the bins.

After the signal “Evacuation!” the light is turned off inside the aircraft and the emergency lightning turns on. After that the prepared flight attendants open the doors and activate the emergency escape slides and assist the passengers. Those who work with the aircraft are allowed to take part in the test as crew members only. I had the easiest role – I was the first to jump out and make the way out from the cabin for the others, and also help to move away from the slide when down under the aircraft so that there was no jam there. Other “crew members” were supposed to take the flashlight, the little axe, the radio and other items with them – everyone had its own instruction. And they were the last to leave the aircraft. According to the certification rules there is only 90 seconds to evacuate from the plane. Everything was good and we had a lot of time left.

The tests still continue nowadays. Any aircraft type while it is under operation needs additional certification tests, though now they serve the goal of further improvements –expanding the flight conditions and increase of dispatch reliability within the carriers’ fleets. That is why our test SSJ100 are still in service. The Customers give us their requirements, the technologies develop, the equipment changes – the aircraft improvement is a never ending job.

Source: SCAC